Contact Us

Contact Us

The Flowability Tester BEP2 has been specifically designed to address the specifications by the Ph. Eur. and USP on Powder Flow. The Flowability Tester BEP2 from Copley provides a range of options for testing pharmaceutical powders including three of the four methods quoted in the Pharmacopoeias – flow through an orifice, angle of repose and shear cell – in a single, cost effective unit.

请选择以下某个附件,详细了解BEP2型流动性测试仪

Flow-Through an Orifice (Cylinder)

Comprising a stainless-steel cylinder measuring 76 mm long x 57 mm and a capacity of 200 mL, each attachment comes complete with 20 interchangeable stainless-steel disks each with a precision drilled hole between 4 mm and 36 mm.

The cylinder attachment can be used in two different ways:

- For quantitative flowability tests based on mass vs time

- To determine the intrinsic flowability of a powder via a flowability index based on comparative measurements.

The addition of our Balance/Timer Attachment to the shutter mechanism simplifies Mass vs Time tests.

Pharmacopoeial Compliance: |

Ph. Eur. 2.9.36 and 2.9.16 USP <1174> |

Catalogue Number 1650: |

Flowability Tester Model BEP2 Stand and Upright |

Catalogue Number 1655: |

圆柱附件 |

Catalogue Number 1653: |

Balance/Timer Attachment |

The Flowability Tester BEP2 has been specifically designed to address the specifications by the Ph. Eur. and USP on Powder Flow. The Flowability Tester BEP2 from Copley provides a range of options for testing pharmaceutical powders including three of the four methods quoted in the Pharmacopoeias – flow through an orifice, angle of repose and shear cell – in a single, cost effective unit.

请选择以下某个附件,详细了解BEP2型流动性测试仪

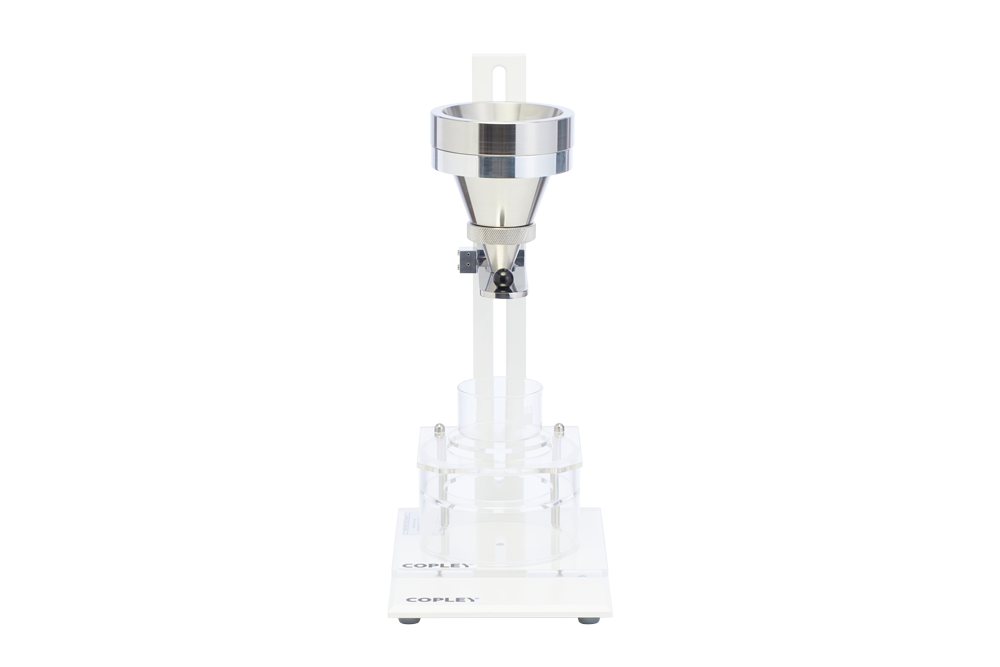

Flow-Through an Orifice (Funnel)

Based on the unit described in Ph.Eur. 2.9.16 for Flowability, the stainless steel funnel and nozzles are designed to simulate flow in a hopper or other similar production situation.

Supplied with 10 mm, 15 mm and 25 mm aperture quick-change nozzles, the funnel is manufactured from pharmaceutical grade 316 stainless steel. Testing is carried out with an easy-to-use shutter.

The addition of our Balance/Timer Attachment to the shutter mechanism simplifies Mass vs Time tests.

Catalogue Number 1650: |

Flowability Tester Model BEP2 Stand and Upright |

Catalogue Number 1652: |

Funnel Attachment |

Catalogue Number 1656: |

Manually Operated Stirrer for Funnel Attachment |

Catalogue Number 1653: |

Balance/Timer Attachment |

The Flowability Tester BEP2 has been specifically designed to address the specifications by the Ph. Eur. and USP on Powder Flow. The Flowability Tester BEP2 from Copley provides a range of options for testing pharmaceutical powders including three of the four methods quoted in the Pharmacopoeias – flow through an orifice, angle of repose and shear cell – in a single, cost effective unit.

请选择以下某个附件,详细了解BEP2型流动性测试仪

Shear Cell

Copley’s cylindrical shear cell attachment is ideal for determining flow properties based on the bulk density and shear strength of fine-grained powders and bulk solids.

Providing important information on a given material’s behaviour in bins, hoppers, feeders and other handling equipment, the Copley shear cell enables precise control of test parameters for a wide range of flowability measurements.

Catalogue Number 1650: |

Flowability Tester Model BEP2 Stand and Upright |

Catalogue Number 1651: |

Shear Cell Attachment* *Requires the Funnel Attachment (catalogue number 1652) to operate |

The Flowability Tester BEP2 has been specifically designed to address the specifications by the Ph. Eur. and USP on Powder Flow. The Flowability Tester BEP2 from Copley provides a range of options for testing pharmaceutical powders including three of the four methods quoted in the Pharmacopoeias – flow through an orifice, angle of repose and shear cell – in a single, cost effective unit.

请选择以下某个附件,详细了解BEP2型流动性测试仪

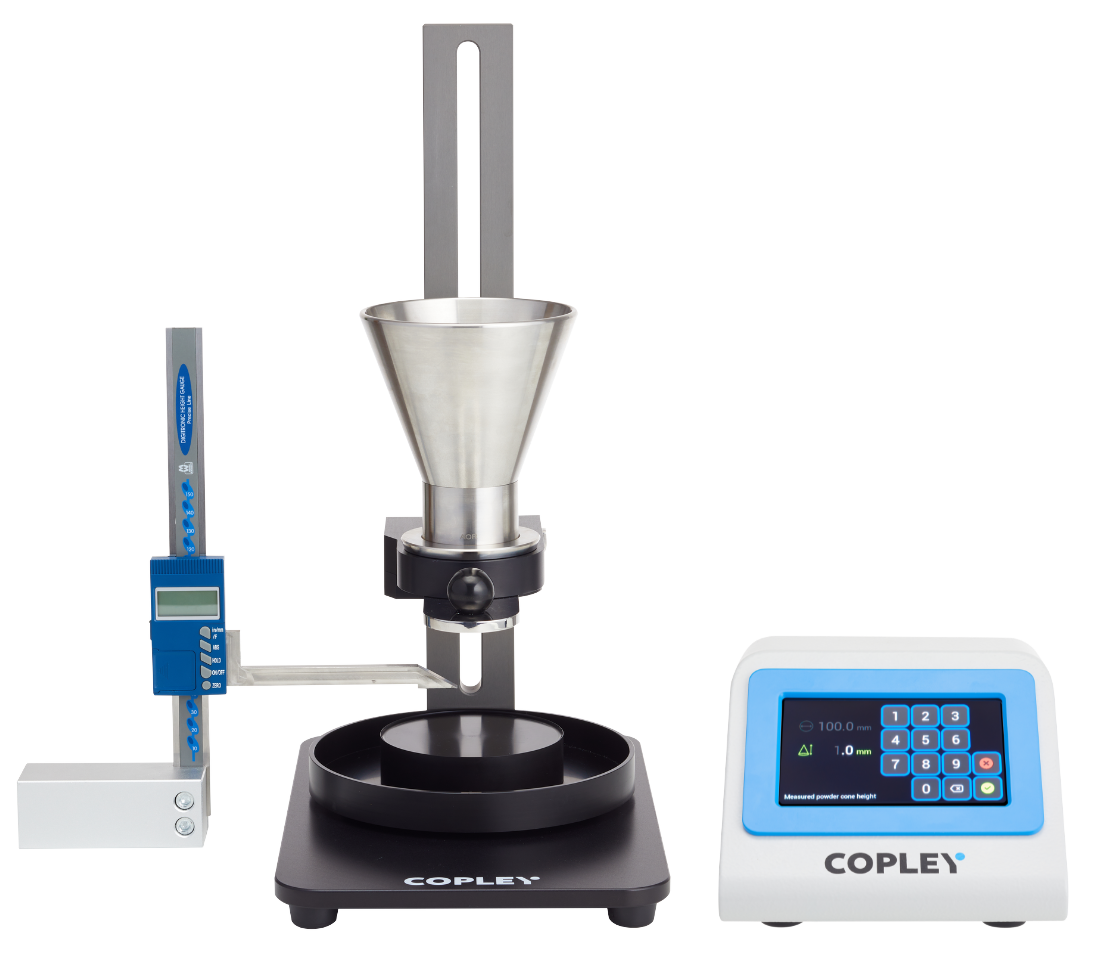

Angle of Repose

Providing a simple method for assessing the friction characteristics of powders, the Copley angle of repose attachment is ideal for predicting manufacturing issues associated with resistance to movement between particles.

Comprising a 100 mm diameter circular test platform together with a digital gauge, powder heights of up to 300mm can be easily read from the clear gauge display. Simply dividing this value by 50 calculates the angle of repose.

Catalogue Number: 1650 |

Flowability Tester Model BEP2 Stand and Upright |

Catalogue Number: 1654 |

Angle of Repose Attachment* *Requires the Funnel Attachment (catalogue number 1652) to operate |