5 August 2014; Nottingham, UK: The desire to gain a better understanding of how inhaled products perform in patients has highlighted the importance and value of achieving better correlations between in-vitro test data and in-vivo performance – better IVIVCs. This deepened interest has been echoed by the US FDA, for example, through research grants supporting the identification of realistic in-vitro clinically relevant representations of the human throat, as well as a dissolution method for inhaled product testing.

To help meet this pressing need for better IVIVCs, Copley Scientific has refined the design of a number of pieces of in-vitro testing equipment to enable a streamlined, easy-to-use, and compact test set-up for more clinically representative testing of orally inhaled products (OIPs). The proposed set-up uses new components alongside established equipment to deliver data that represent in-vivo behaviour more accurately than data from standard test methodologies, originally designed for application in a QC environment.

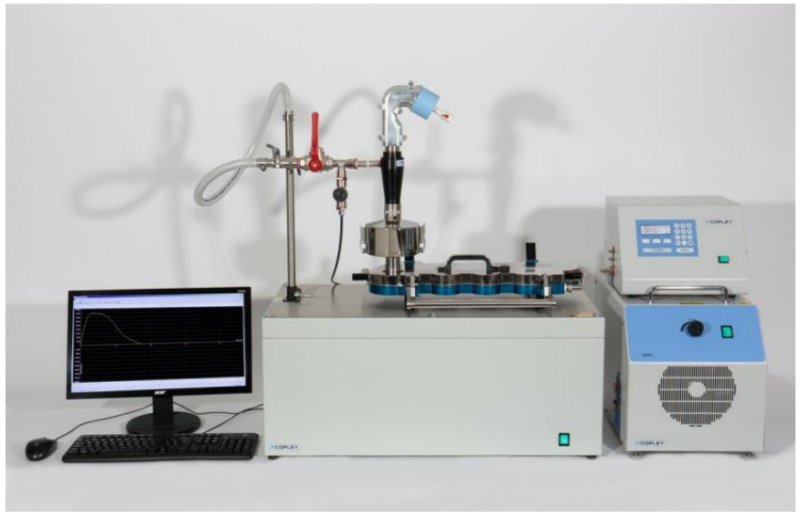

Achieving closer correlation between routine laboratory data and the efficiency of drug delivery to specific regions of the lung is an important goal in inhaled product testing. Better IVIVCs support the advancement of new OIP products and technology. They also underpin the secure demonstration of bioequivalence, a critical step in the development of generic OIPs and help reduce the risk of unexpected outcomes in clinical trials. The proposed new test set-up from Copley Scientific comprises: the Alberta Idealized Throat (AIT); a mixing inlet; a breath simulator; vacuum pump and critical flow controller.

Either a child or adult version of the AIT can be used depending on the target patient group. The AIT has been shown to more precisely reflect deposition behaviour in the throat than the standard USP induction port routinely used in testing. It therefore enables more precise measurement of the quantity and aerodynamic particle size of drug particles entering the lungs.

Separate mixing inlet designs are now available for use with both the Andersen Cascade Impactor (ACI) and Next Generation Impactor (NGI). These impactors are used for measuring the aerodynamic particle size distribution (APSD) of all OIPs to help infer likely deposition behaviour in the lung, specific to the active pharmaceutical ingredient (API). By using a mixing inlet, it is possible to apply a breath profile through the OIP device during testing that reflects that of the target patient group, while maintaining a constant flow rate through the impactor. This allows the user to maintain the operating (sampling) conditions required of the impactor whilst simultaneously testing the device under patient representative conditions.

The test set-up is completed with the BRS 3000 Breath Simulator, which enables close control of the breath profile applied to the inhaler during testing. A vacuum pump and critical flow controller (such as the TPK 2000-R) are used to enable accurate, stable, regulated flow through the impactor. Standard compressed air fittings, a flow manifold with 3-way valve, and an accessory stand, further support an effective, space-efficient test set-up. A breath profile verification chamber along with a flow certifier are also available to allow real-time recording and documentation of profiles generated for validation purposes.

CAPTION: A streamlined test set-up for achieving better IVIVCs in OIP testing, shown here with the Adult Alberta Idealized Throat.

About Copley Scientific

Copley Scientific is recognised as the world’s leading manufacturer and supplier of inhaler test equipment and is a major provider of testing systems for other pharmaceutical dosage forms. The company is also active in detergent testing, air sampling and aerosol characterisation.

Copley Scientific’s pharmaceutical product range includes test equipment for: delivered dose uniformity and aerodynamic particle size measurement of metered-dose inhalers, dry powder inhalers, nebulizers and nasal sprays; as well as tablets (dissolution, disintegration, friability and hardness) capsules, powders, suppositories and transdermals.

Copley Scientific has offices in the UK and Switzerland. The company works in partnership with aerosol particle science experts MSP Corporation in North America, and also distributes MSP Corporation’s air sampling and aerosol characterisation products throughout Europe.

Serving the pharmaceutical and associated industries, Copley Scientific offers an extensive range of equipment for research, development and quality control, as well as full validation and aftersales services. This broad range of products is supplied and supported worldwide through a network of specialist distributors.