Contact Us

Contact Us

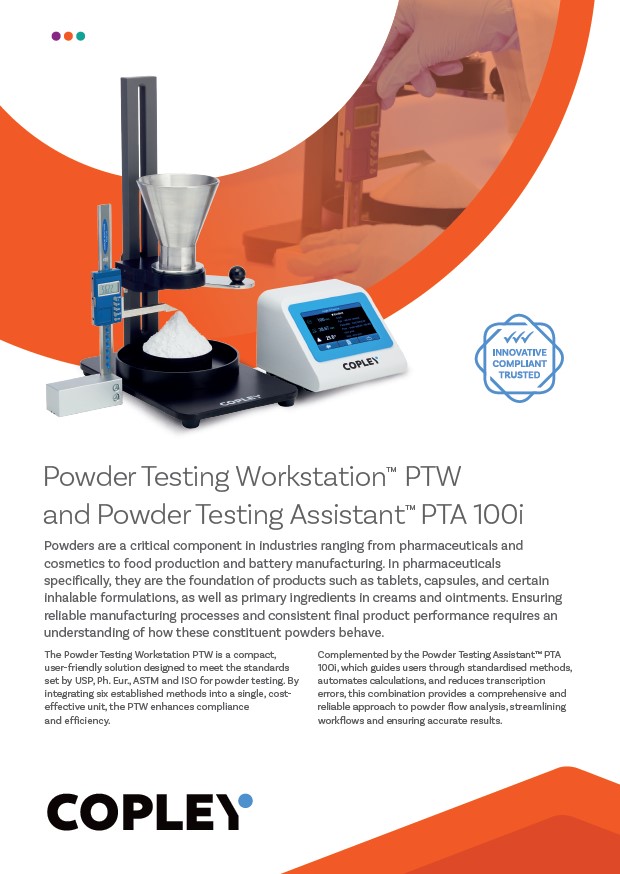

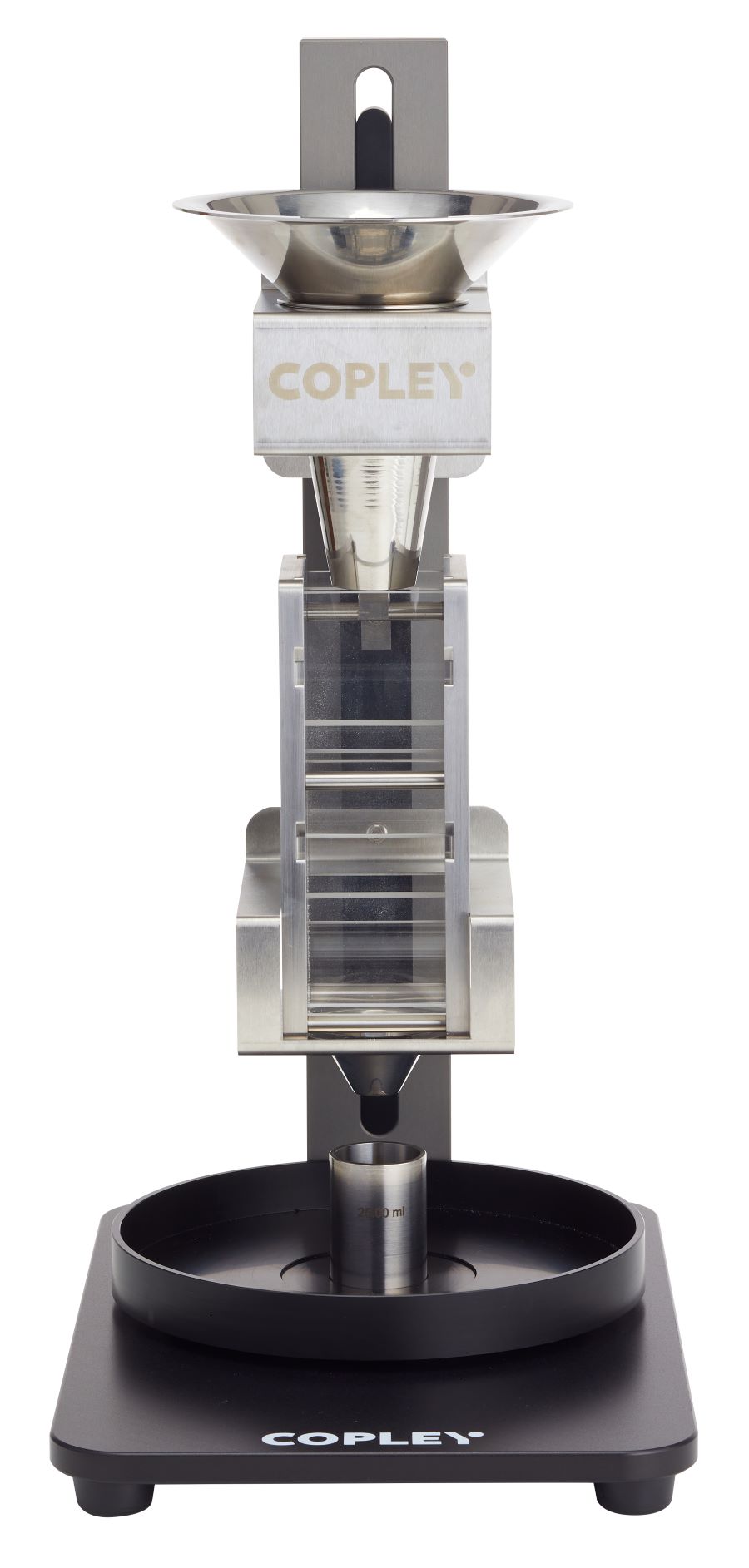

The Powder Testing Workstation PTW has been specifically designed to meet the standards outlined by USP, Ph. Eur., ASTM, and ISO for powder flow testing. The PTW provides a versatile solution, integrating six powder testing methods into a single, cost-effective unit, including Angle of Repose, Flow Through an Orifice via Cylinder and Funnel, Bulk Density via Scott Volumeter and Shear Cell, plus Flowability and Bulk Density of Metal Powders (Hall, Gustavsson and Carney Flowmeter).

Please select one of the modules below to find out more about the Powder Testing Workstation PTW:

Angle of Repose

Providing a simple method for assessing the frictional characteristics of powders, the Copley Angle of Repose module is ideal for predicting manufacturing issues associated with gravitational flow.

Comprising a 100 mm diameter circular test platform together with a digital height gauge, powder heights of up to 145 mm can be easily read from the clear display.

The tangent of the Angle of Repose (θ) is determined by measuring the height of the powder cone in mm and dividing it by 50. The inverse tangent of this figure provides the Angle of Repose in degrees.

Pharmacopoeial Compliance: |

Ph. Eur. Chapter 2.9.36 USP <1174> |

Catalogue Number: 1670 |

Powder Testing station PTW Stand and Shutter |

Catalogue Number: 1674 |

Angle of Repose Attachment |

Catalogue Number 1676: |

Stirrer Attachment for PTW |

Catalogue Number 1677: |

Anti-static Grounding Kit |

Catalogue Numbers: 1673 |

Balance options: Kern Balance – 1. D.P 10000g Max Kern Balance – 2 D.P 400g Max Ohaus Balance – 3 D. P 440g Max |

Catalogue Number 1680: |

Powder Testing Assistant™ PTA 100i |

The Powder Testing Station PTW has been specifically designed to meet the standards outlined by USP, Ph. Eur., ASTM, and ISO for powder flow testing. The PTW provides a versatile solution, integrating six powder testing methods into a single, cost-effective unit, including Angle of Repose, Flow Through an Orifice via Cylinder and Funnel, Bulk Density via Scott Volumeter and Shear Cell, plus Flowability and Bulk Density of Metal Powders (Hall, Gustavsson and Carney Flowmeter).

Please select one of the modules below to find out more about the Powder Testing Workstation PTW:

Flow-Through an Orifice via Cylinder

Comprising a stainless-steel cylinder measuring 76 mm x 57 mm and a capacity of 200 mL, each module comes complete with 20 interchangeable stainless-steel disks with a precision orifice from 4 to 36 mm.

Flow Through an Orifice tests can be undertaken in several ways:

- Quantitative flowability test based on fixed mass or fixed time to understand the uniformity and consistency of power flow

- Intrinsic flow properties of a powder via a Flowability Index based on comparative assessments

Pharmacopoeial Compliance: |

Ph. Eur. 2.9.36 and 2.9.16 USP <1174> |

Catalogue Number 1670: |

Powder Testing Workstation PTW Stand and Shutter |

Catalogue Number 1671: |

Cylinder Attachment |

Catalogue Number 1678: |

Timer Attachment |

Catalogue Number 1677: |

Anti-static Grounding Kit |

Catalogue Numbers: 1673 |

Balance options: Kern Balance – 1. D.P 10000g Max Kern Balance – 2 D.P 400g Max Ohaus Balance – 3 D. P 440g Max

|

Catalogue Number 1680: |

Powder Testing Assistant™ PTA 100i |

The Powder Testing Workstation PTW has been specifically designed to meet the standards outlined by USP, Ph. Eur., ASTM, and ISO for powder flow testing. The PTW provides a versatile solution, integrating six powder testing methods into a single, cost-effective unit, including Angle of Repose, Flow Through an Orifice via Cylinder and Funnel, Bulk Density via Scott Volumeter and Shear Cell, plus Flowability and Bulk Density of Metal Powders (Hall, Gustavsson and Carney Flowmeter).

Please select one of the modules below to find out more about the Powder Testing Workstation PTW:

Flow-Through an Orifice via Funnel

Designed in accordance with USP <1174> and Ph. Eur. Chapters 2.9.36 and 2.9.16 for Flowability, the stainless-steel funnel and nozzles simulate flow in a hopper or other similar production equipment.

Supplied with 5, 7, 10, 15 and 25 mm aperture quick-change nozzles, the funnel is manufactured from pharmaceutical grade 316 stainless steel. Testing is performed using a simple, user-friendly shutter system.

Optional Balance and Timer attachments further simplify mass vs time tests.

Pharmacopoeial Compliance: |

Ph. Eur. 2.9.36 and 2.9.16 USP <1174> |

Catalogue Number 1670: |

Powder Testing Workstation PTW Stand and Shutter |

Catalogue Number 1672: |

Funnel Attachment |

Catalogue Number 1678: |

Timer Attachment |

Catalogue Number 1677: |

Anti-static Grounding Kit |

Catalogue Numbers: 1673 |

Balance options: Kern Balance – 1. D.P 10000g Max Kern Balance – 2 D.P 400g Max Ohaus Balance – 3 D. P 440g Max |

Catalogue Number 1680: |

Powder Testing Assistant™ PTA 100i |

The Powder Testing Workstation PTW has been specifically designed to meet the standards outlined by USP, Ph. Eur., ASTM, and ISO for powder flow testing. The PTW provides a versatile solution, integrating six powder testing methods into a single, cost-effective unit, including Angle of Repose, Flow Through an Orifice via Cylinder and Funnel, Bulk Density via Scott Volumeter and Shear Cell, plus Flowability and Bulk Density of Metal Powders (Hall, Gustavsson and Carney Flowmeter).

Please select one of the modules below to find out more about the Powder Testing Workstation PTW:

Bulk Density via Scott Volumeter

The Scott Volumeter is described in both USP and Ph. Eur. and is suitable for evaluating the bulk density of a diverse range of powders and granules.

A comparison of the bulk and tapped density of a powder provides valuable insight into behaviour during handling and storage and can be used to determine well-established metrics of Carr’s Index and Hausner Ratio.

Regulatory Compliance: |

Ph. Eur. 2.9.34 USP <616> ISO-3923-2 1981 ASTM B329-20 |

Catalogue Number 6310: |

Scott Volumeter and a Powder Testing Workstation PTW |

Catalogue Number 1680: |

Powder Testing Assistant™ PTA 100i |

The Powder Testing Workstation PTW has been specifically designed to meet the standards outlined by USP, Ph. Eur., ASTM, and ISO for powder flow testing. The PTW provides a versatile solution, integrating six powder testing methods into a single, cost-effective unit, including Angle of Repose, Flow Through an Orifice via Cylinder and Funnel, Bulk Density via Scott Volumeter and Shear Cell, plus Flowability and Bulk Density of Metal Powders (Hall, Gustavsson and Carney Flowmeter).

Please select one of the modules below to find out more about the Powder Testing Workstation PTW:

Shear Cell

The Shear Cell module helps determine how static, consolidated powders transition into flow, providing valuable insight into powder behaviour in hoppers, bins, feeders and other powder handling equipment. The Copley Shear Cell provides a simple, cost-effective method for understanding the incipient flow properties of bulk solids.

Catalogue Number 1670: |

Powder Testing Workstation PTW Stand and Shutter |

Catalogue Number 1677: |

Anti-static Grounding Kit |

Catalogue Numbers: 1673 |

Balance options: Kern Balance – 1. D.P 10000g Max Kern Balance – 2 D.P 400g Max Ohaus Balance – 3 D. P 440g Max |

Catalogue Number 1680: |

Powder Testing Assistant™ PTA 100i |

The Powder Testing Workstation PTW has been specifically designed to meet the standards outlined by USP, Ph. Eur., ASTM, and ISO for powder flow testing. The PTW provides a versatile solution, integrating six powder testing methods into a single, cost-effective unit, including Angle of Repose, Flow Through an Orifice via Cylinder and Funnel, Bulk Density via Scott Volumeter and Shear Cell, plus Flowability and Bulk Density of Metal Powders (Hall, Gustavsson and Carney Flowmeter).

Please select one of the modules below to find out more about the Powder Testing Workstation PTW:

Metal Powder Flow

The Metal Powder Flow module is designed to evaluate the flowability of metal powders in accordance with several ISO and ASTM standards. Incorporating Hall, Gustavsson and Carney Flowmeter methods, it provides insight into fundamental flow properties which directly impact performance in processes such as filling, spreading and compaction.

ISO and ASTM Compliance: |

ISO 3923:2018 ISO 4490:2018 ISO 13517:2020 ASTM B213-20 ASTM B417-22 ASTM B964-23 |

Catalogue Number: 1670 |

Powder Testing Workstation PTW Stand and Shutter |

Catalogue Number 1681: |

Metal Powder Testing Apparatus |

Catalogue Number 1677: |

Anti-static Grounding Kit |

Catalogue Numbers: 1673 |

Balance options: Kern Balance – 1. D.P 10000g Max Kern Balance – 2 D.P 400g Max Ohaus Balance – 3 D. P 440g Max |

Catalogue Number 1680: |

Powder Testing Assistant™ PTA 100i |

Powder Testing Workstation PTW

Enables six established test methods

Compliant with USP, Ph. Eur., ASTM, and ISO standards

Engineered from lightweight and durable materials ensuring long-life and easy maintenance

Compatible with the Powder Testing Assistant PTA 100i

The Powder Testing Workstation PTW is now available with the Powder Testing Assistant PTA 100i

The complementary PTA 100i optimises powder testing processes by guiding users through test methods step-by-step, automating measurements and calculations, and recording results, helping to establish robust test protocols and maintain data integrity. The unique combination of the PTW and PTA 100i provides an innovative approach to powder flow analysis combining versatility and accuracy to enhance efficiency and ensure reliable results.

View PTA 100i

The PTW is compliant with a range of other industrial standards, including:

- ISO 3923-1:2018 – Metallic Powders

- ISO 4490:2018 – Metallic Powders (Hall Flowmeter)

- ISO 13517:2020 – Metallic Powders (Gustavsson Flowmeter)

- ASTM B213-20 – Metal Powders (Hall Funnel)

- ASTM B417-22 – Non-Free-Flowing Metal Powders (Carney Funnel)

- ASTM B964-23 – Metal Powders (Carney Funnel)

- ASTM B329-20 – Metal Powders

- ISO 3923-2:1981 – Metallic Powders

Related Accessories

Related Services

Training

We offer a range of training courses, presentations and seminars covering a wide range of topics.

Find Out More

Servicing

A comprehensive range of both in-house and on-site product servicing options are available

Find Out More

Support

Our team of experienced technicians and engineers are on hand to help and advise

Find Out More