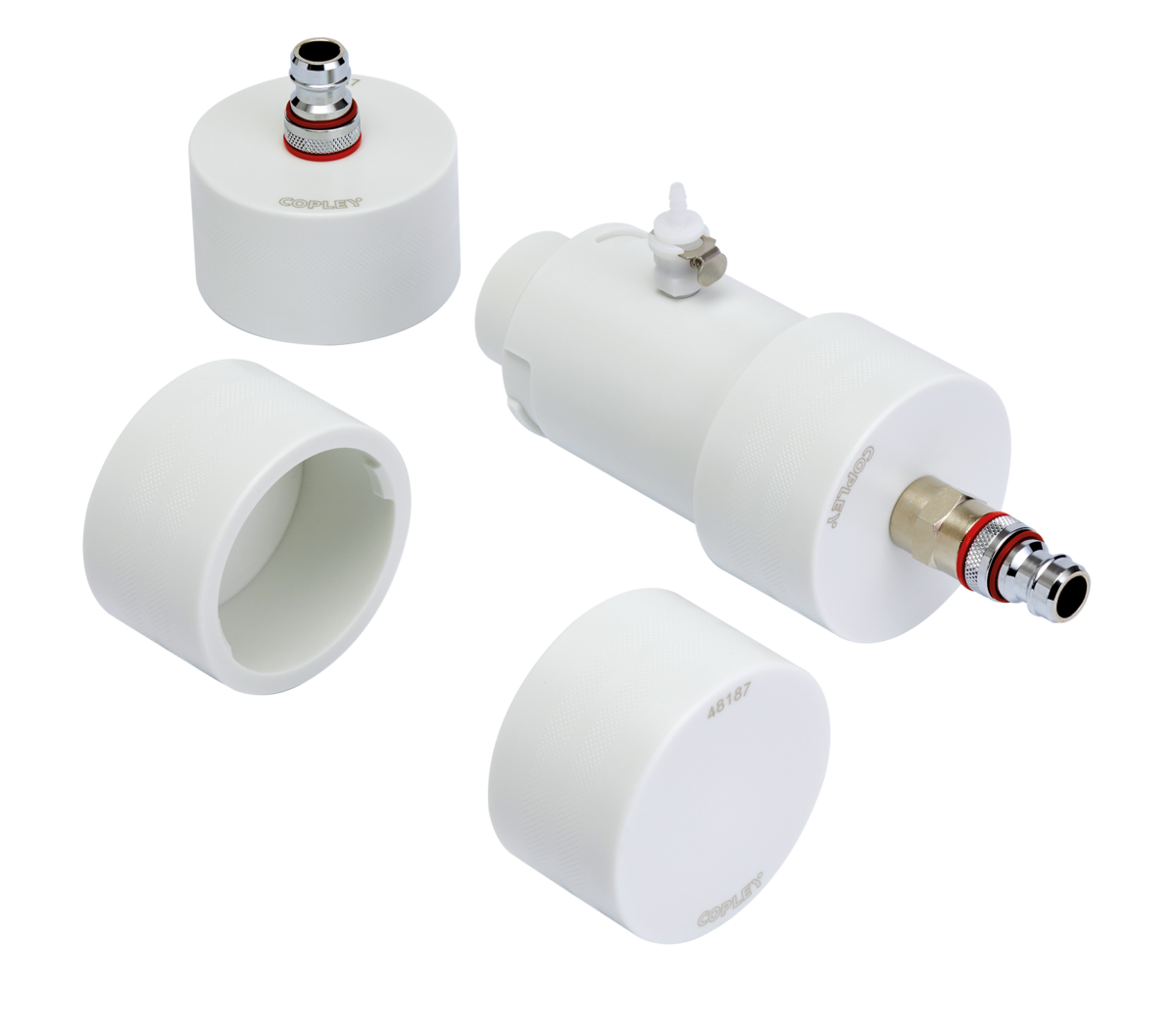

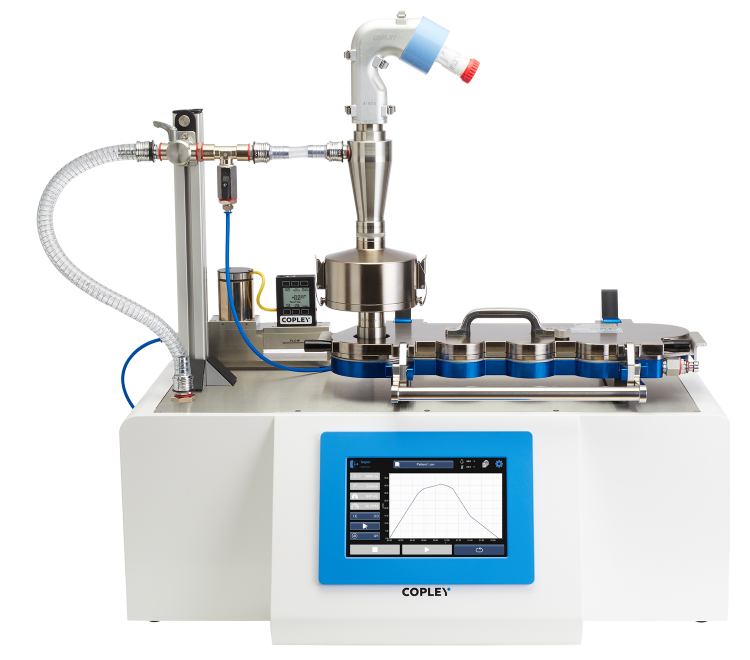

Delivered Dose Uniformity (DDU)

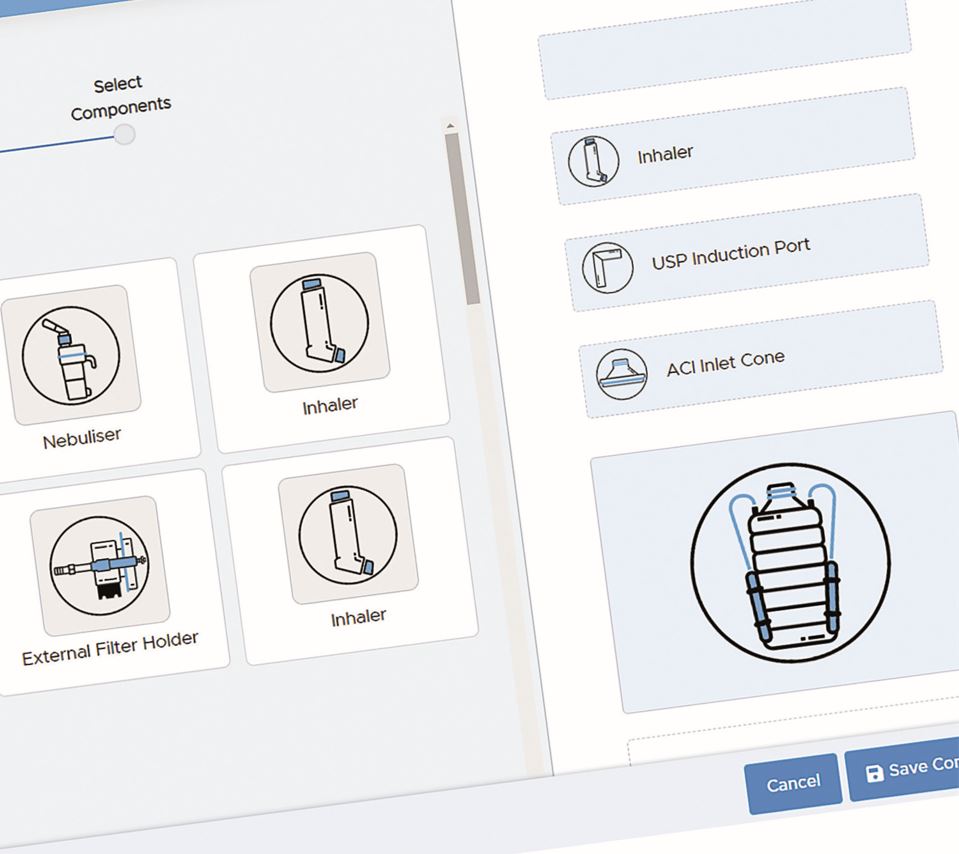

Our range of Delivered Dose Uniformity (DDU) sampling apparatus are designed to help accurately assess the total amount of emitted drug.

View More Details

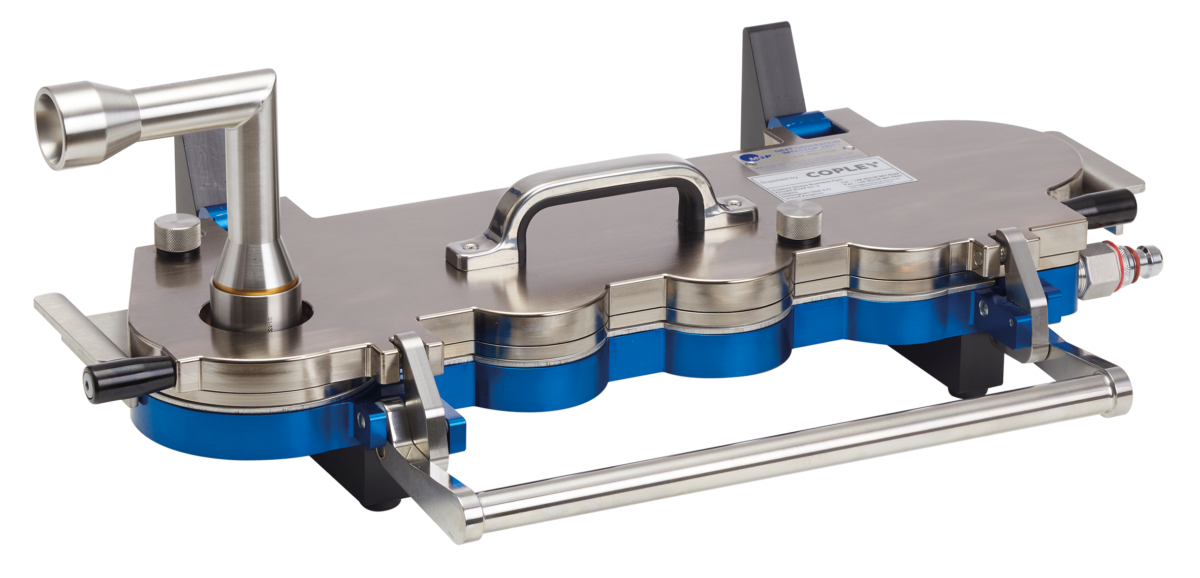

Aerodynamic Particle Size Distribution (APSD)

Our range of precision engineered cascade impactors measure the size distribution (particle size) of inhaled drug products, providing critical information about where particles in aerosol clouds are likely to be deposited in the lungs following inhalation.

View More Details

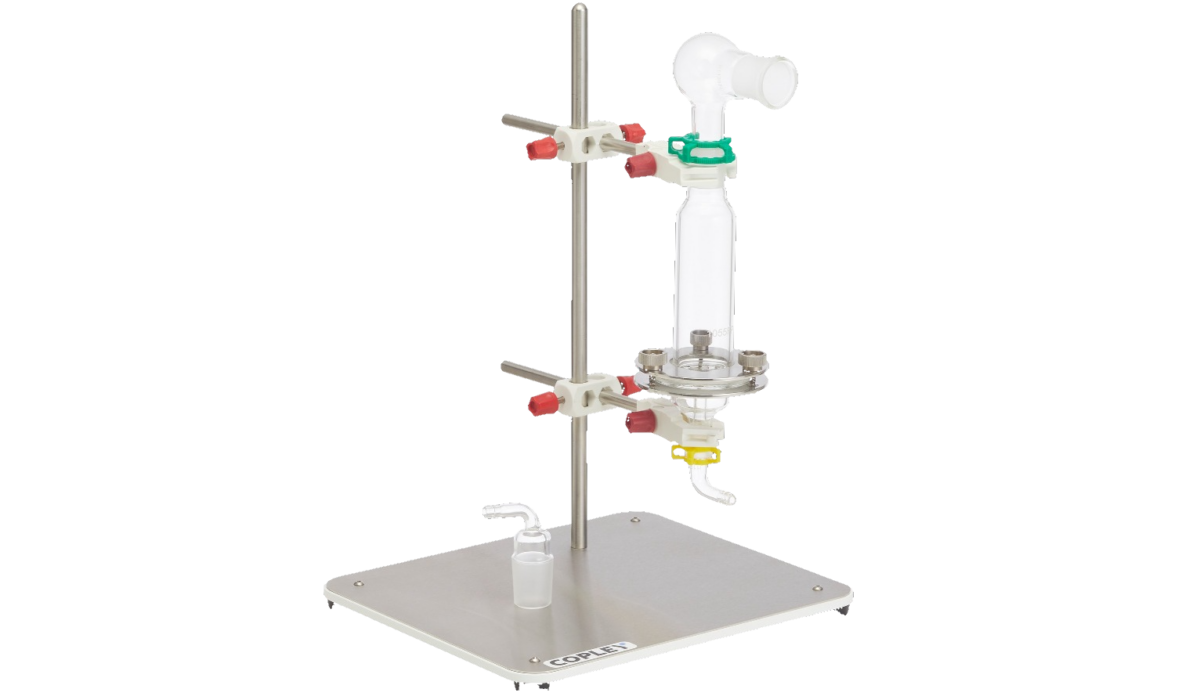

Ancillaries

Optimise inhaler testing workflows with our broad range of supporting equipment required to make up fully-operating test systems for Delivered Dose Uniformity (DDU) and Aerodynamic Particle Size Distribution (APSD) of orally inhaled and nasal drug products (OINDPs).

View More Details

APSD Data Analysis Software

Inhalytix® – Efficiently converts raw APSD data into performance-defining metrics for all OINDPs

View More Details

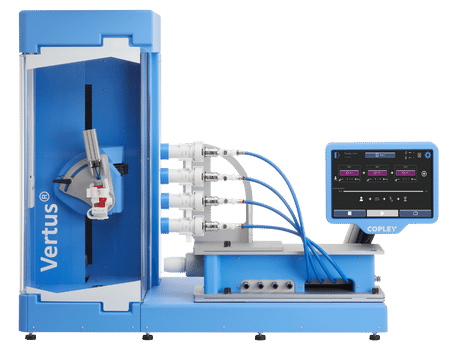

Automation

Take the labour out of inhaler testing with our semi-automated solutions.

View More Details

Special Applications

Copley Scientific offers a range of testing equipment for additional qualification and validation of orally inhaled and nasal drug products (OINDPs), including assessments of generic drug formulations, inhaled dissolution testing and improving IVIVCs.

View More Details

Improving IVIVCs

Better IVIVC has long been an industry aim. This is particularly difficult in the case of inhaled and nasal products because of the complications involved in precisely correlating drug deposition behaviour with clinical efficacy, the impact of patient-to-patient variability and the complex interaction between formulation and device.

View More Details

Realistic Throat and Nasal Cavity Model

The drug mass sized by the cascade impactor (impactor sized mass) should ideally be representative of the dose that would actually enter the lungs. To achieve this, the induction port or other accessory used to interface the device to the impactor must capture a representative fraction of the dose. Our throat and nasal models have a standardised internal geometry more representative of in vivo physiology than a standard induction port and suitable for a range of patient profiles.

View More Details

Inhaler Development Testing Services

Training

We offer a range of training courses, presentations and seminars covering a wide range of topics.

Find Out More

Servicing

A comprehensive range of both in-house and on-site product servicing options are available

Find Out More

Support

Our team of experienced technicians and engineers are on hand to help and advise

Find Out More