Contact Us

Contact Us

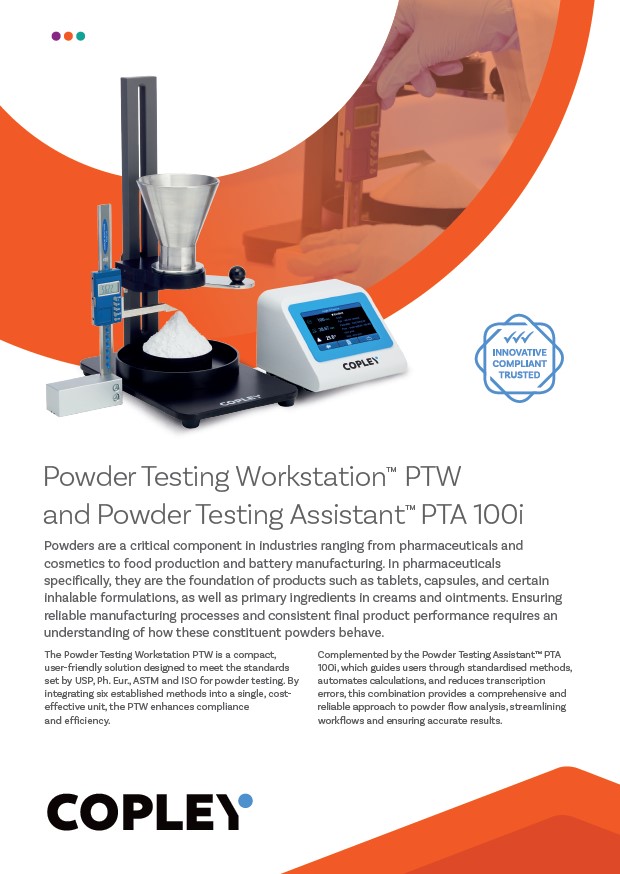

Please select one of the DISi Series dissolution testers for further product information

Easy-clean Viton® membrane-sealed zero-evaporation lids included as standard

Intuitive touchscreen control with icon-based menu structure simplifies operation

Robust metal case with advanced corrosion protective coating

PT100 temperature probe monitors bath and vessel temperature with electronic calibration feature

Independent digital heater/circulator maintains a constant temperature and minimises vibration

Easily removable leak-proof water bath with convenient drain tap eases bath water emptying

All vessels are serial-numbered as standard

Convenient screw-in basket/paddles enable easy method change in seconds

Maximum fill line indicator

‘Easy-Centre’ centring system for precise vessel positioning

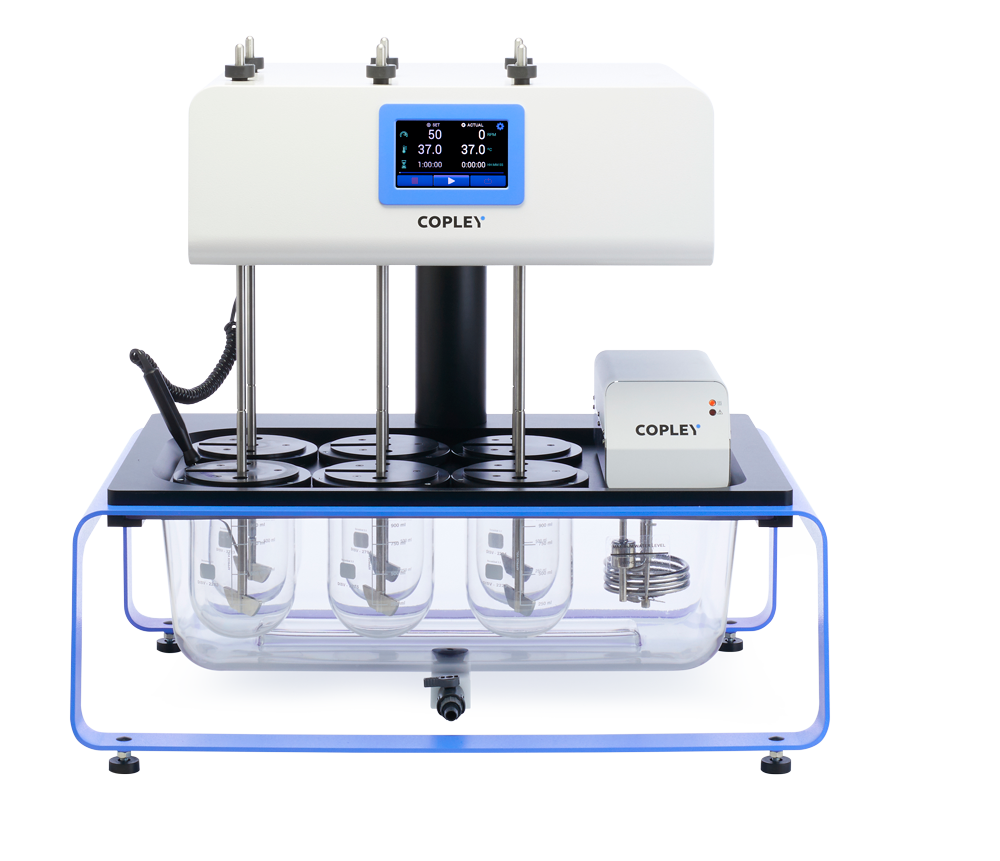

DIS 600i

With bench space a premium in many laboratories, the DIS 600i is one of the most compact dissolution test for tablets available on the market today.

Ideal for use in both R&D and QC environments, the DIS 600i is equipped with precision ground shafts that will accept any of the baskets, paddles or rotating cylinders described in the Ph. Eur., USP and associated Pharmacopoeias.

Catalogue Number: |

1336 |

Pharmacopoeial Compliance: |

Ph. Eur. 2.9.3 and 2.9.4 USP <711> and <724> |

Ph. Eur. and USP Test Methods Supported: |

1, 2, 5, 6 |

Number of Stirred Vessels: |

6 |

Heater Type: |

Low vibration independent external digital heater/circulator |

Unit Dimensions (w x d x h): |

728 x 495 x 689 mm (unit) |

Please select one of the DISi Series dissolution testers for further product information

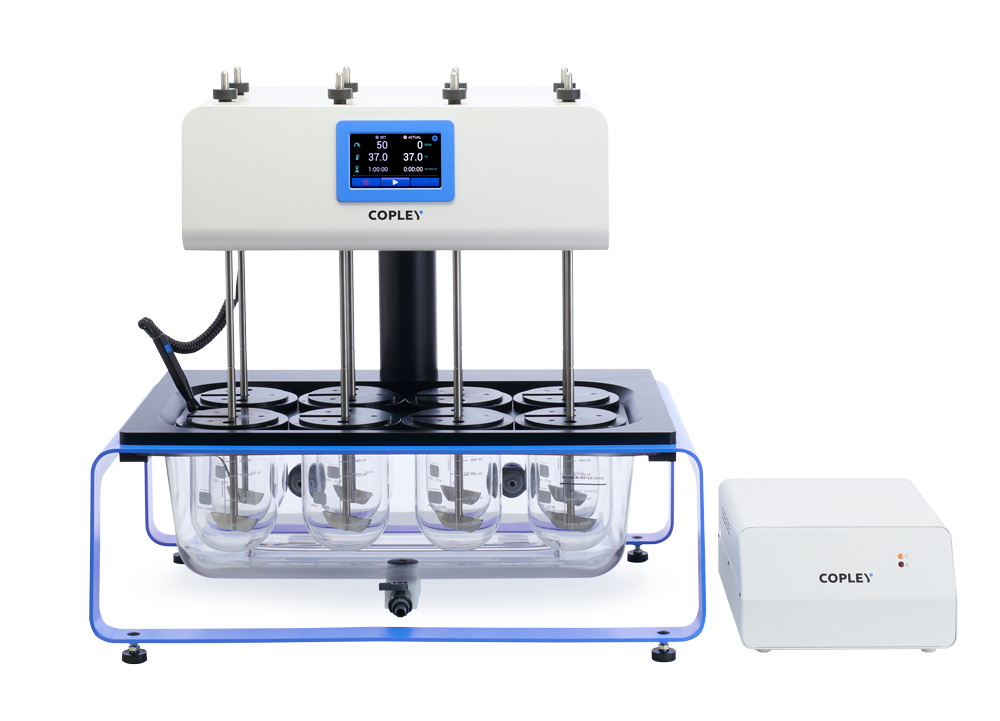

Easy-clean Viton® membrane-sealed low evaporation lids included as standard

Intuitive touchscreen control with icon-based menu structure simplifies operation

Robust metal case with advanced corrosion protective coating

PT100 temperature probe monitors bath and vessel temperature with electronic calibration feature

Independent digital heater/circulator maintains a constant temperature and minimises vibration

‘Easy-Centre’ centring system for precise vessel positioning

Maximum fill line indicator

Convenient screw-in basket/paddles enable easy method change in seconds

All vessels are serial-numbered as standard

Easily removable leak-proof water bath with convenient drain tap eases bath water emptying

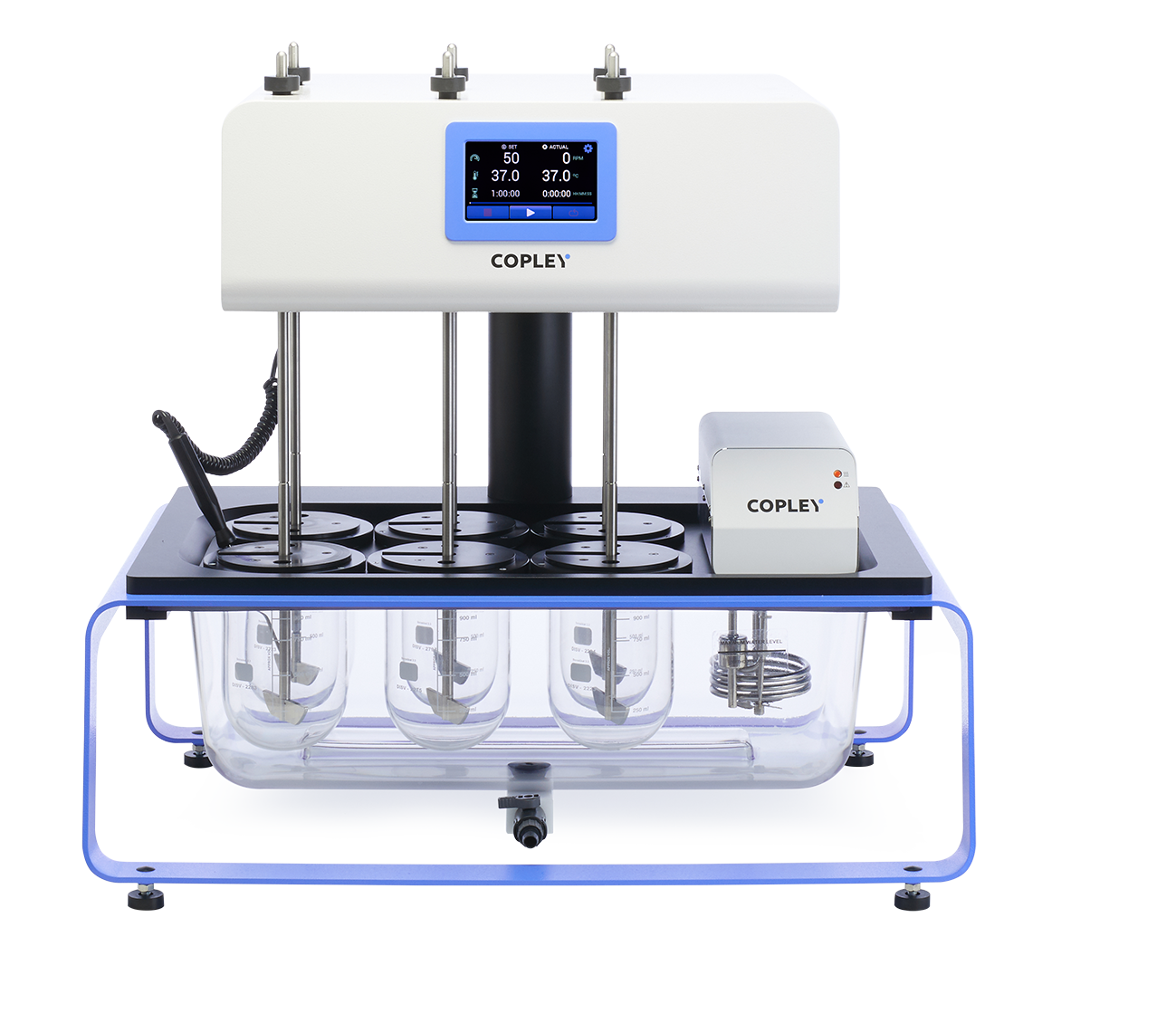

DIS 800i

Maximising visibility and access to the critical sampling area above the bath, the DIS 800i represents the very latest in tablet testing technology.

Ideal for use in both R&D and QC environments, the DIS 800i is equipped with precision ground shafts that will accept any of the baskets, paddles or rotating cylinders described in the Ph. Eur., USP and associated Pharmacopoeias.

Catalogue Number: |

1338 |

Pharmacopoeial Compliance: |

Ph. Eur. 2.9.3 and 2.9.4 USP <711> and <724> |

Eur. Ph & USP Test Methods Supported: |

|

Number of Stirred Vessels: |

8 |

Heater Type: |

Low vibration independent external digital heater/circulator |

Unit Dimensions (w x d x h): |

728 x 495 x 689 mm (without heater) 260 x 330 x 150 mm (heater) |

Key DISi Series Highlights

DISi Series dissolution testers are Ph. Eur. and USP compliant

Integrated, precision temperature control and measurement

Intuitive touchscreen control to simplify operation

Single-point electronic temperature calibration

Six and eight test station unit configurations available

Extensive data reporting output options: RS 232, USB A and USB B

Wide speed range to accommodate broad scope of methods

Option to automate and remotely control DISi Series systems

DISi Dissolution Tester Series

DISi Sampling Alerts

- Enter timepoints for sampling

- Begin testing

- Receive warning alert prior to sample timepoint

- Get alerted at the required sample timepoint

- Never miss a sample!

DISi Compliance & Maintenance

- Certificate of compliance to Ph. Eur./USP provided as standard

- Comprehensive IQ/OQ/PQ documentation packages and toolkits available

- Passcode-protected single-point electronic temperature calibration

- Latest temperature calibration information stored and available to export/print

DISi Series Calibration Tools

- Calibration of the DISi Series temperature probe is simple, through the use of an electronic calibration key and pin-protected calibration menu designed to guide users through the process without fuss. The latest temperature probe calibration information is stored and available to print/export when convenient to the user.

- To calibrate all other aspects of the DISi Series, our complete range of calibration and qualification tools can be used to safeguard compliance with the appropriate pharmacopoieal and regulatory guidance.

Special Applications

Related Services

Training

We offer a range of training courses, presentations and seminars covering a wide range of topics.

Find Out More

Servicing

A comprehensive range of both in-house and on-site product servicing options are available

Find Out More

Support

Our team of experienced technicians and engineers are on hand to help and advise

Find Out More