19 December 2013; Nottingham, UK: Mark Copley, Sales Director of Copley Scientific, will survey best practice in the use and maintenance of cascade impactors – instruments used to test all inhaled products – in his presentation at the symposium ‘Developments in analysis of orally inhaled and nasal drug products’ in February 2014. The event is organised by the Joint Pharmaceutical Analysis Group (JPAG), whose parent professional bodies are the Royal Pharmaceutical Society and the Royal Society of Chemistry (RSC), and will take place at the RSC in London on 6 February. Find out more or register for the event.

Cascade impaction is used to measure the aerodynamic particle size distribution of all orally inhaled drugs (OIPs) to support targeted drug delivery and ensure product quality. The technique is relatively complex and manually intensive. This makes it is essential to rigorously develop and define methods for its use with any specific OIP. Furthermore, cascade impactors are precision instruments; appropriate maintenance strategies help to ensure compliance and safeguard data integrity.

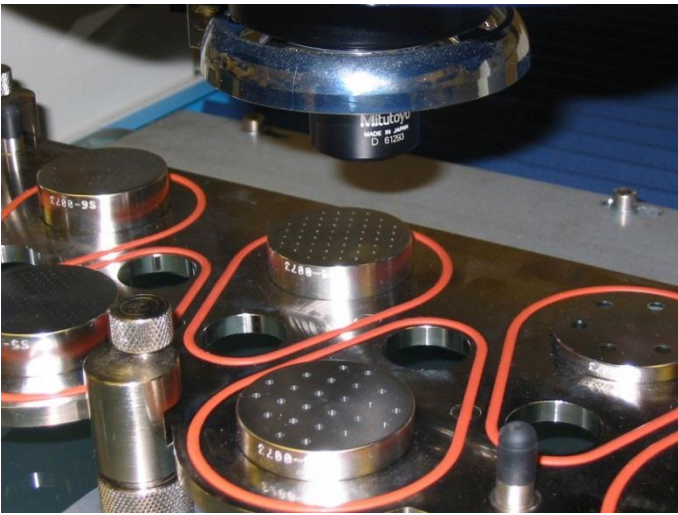

Mark Copley will share his knowledge and experience of how to guarantee optimal cascade impactor performance in a talk entitled: ‘Best practice in cascade impactor qualification’. His focus will be the method validation and system suitability aspects of impactor qualification and will include practical guidance on impactor stage mensuration and leak testing. Stage mensuration is the systematic and precise measurement of the mechanical dimensions of a cascade impactor that confer its aerodynamic performance, and is a vital routine maintenance task. The talk will also provide advice on how to analyse the causes of failures when problems are encountered with either the reported APSD results or impactor mass balance, post analysis.

CAPTION: Stage mensuration; a focus of Mark Copley’s talk on best practice in cascade impaction – JPAG symposium, 6th Feb 2014.

About Copley Scientific

Copley Scientific is recognised as the world’s leading manufacturer and supplier of inhaler test equipment and is a major provider of testing systems for other pharmaceutical dosage forms. The company is also active in detergent testing, air sampling and aerosol characterisation.

Copley Scientific’s pharmaceutical product range includes test equipment for: delivered dose uniformity and aerodynamic particle size measurement of metered-dose inhalers, dry powder inhalers, nebulizers and nasal sprays; as well as tablets (dissolution, disintegration, friability and hardness) capsules, powders, suppositories and transdermals.

Copley Scientific has offices in the UK and Switzerland. The company works in partnership with aerosol particle science experts MSP Corporation in North America, and also distributes MSP Corporation’s air sampling and aerosol characterisation products throughout Europe.

Serving the pharmaceutical and associated industries, Copley Scientific offers an extensive range of equipment for research, development and quality control, as well as full validation and aftersales services. This broad range of products is supplied and supported worldwide through a network of specialist distributors.