8 December 2015; Nottingham, UK: Use of the new Vacuum De-aeration Apparatus from Copley Scientific improves the accuracy of semisolid pharmaceutical testing by efficiently de-gassing the medium used in Vertical Diffusion Cells (VDCs) to measure the drug release profile of these products.

Semisolids are creams, ointments, gels or lotions used principally in the treatment of dermatological conditions that are applied topically to the skin to deliver a localised therapeutic response. The performance of such products is determined by measuring the release rate of the active ingredient, through a suitable membrane held in contact with a receptor medium contained within a VDC.

Air bubbles accumulating on the underside of the membrane are the single largest source of problems in VDC testing. As a result, it is essential that the receptor medium used to bathe the membrane is de-gassed prior to use if the generation of air bubbles, and hence impaired diffusion, is not to take place. United States Pharmacopoeia Chapter <1724>, which specifies the test method for semisolids, calls directly for the de-gassing of the receptor medium ahead of testing to avoid this issue.

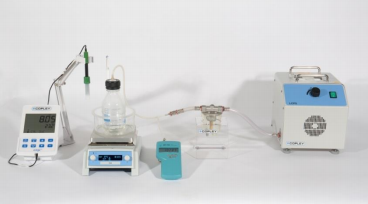

The new Vacuum De-aeration Apparatusfrom Copley Scientific is an inexpensive unit specifically designed to provide a source of pre-warmed, de-gassed media for use in VDCs. It operates by heating the receptor media up to 45o C under vacuum conditions of 90kPa below atmospheric pressure. Performance data suggest that dissolved oxygen can typically be reduced to below 4 ppm within one hour. This compares favourably with the compendial recommendation of less than 6 ppm. To find out more about the new Vacuum De-aeration Apparatus please contact Copley Scientific at sales@copleyscientific.co.uk.

CAPTION: The Vacuum De-aeration Apparatus from Copley Scientific improves accuracy in the testing of pharmaceutical semisolids

About Copley Scientific

Copley Scientific is recognised as the world’s leading manufacturer and supplier of inhaler test equipment and is a major provider of testing systems for other pharmaceutical dosage forms. The company is also active in detergent testing, air sampling and aerosol characterisation. Copley Scientific’s pharmaceutical product range includes test equipment for delivered dose uniformity and aerodynamic particle size measurement of metered-dose inhalers, dry powder inhalers, nebulizers and nasal sprays; as well as tablets (dissolution, disintegration, friability and hardness) capsules, powders, suppositories and transdermals. Copley Scientific has offices in the UK and Switzerland. The company works in partnership with aerosol particle science experts MSP Corporation in North America and also distributes MSP Corporation’s air sampling and aerosol characterisation products throughout Europe. Serving the pharmaceutical and associated industries, Copley Scientific offers an extensive range of equipment for research, development and quality control, as well as full validation and aftersales services. This broad range of products is supplied and supported worldwide through a network of specialist distributors.