The evolution of drug delivery across our 75-year plus history, what it’s meant for pharmaceutical testing, and where the industry is heading next.

The history of drug delivery extends back millennia. Egyptian scrolls from ~1500BC reference the use of inhaled therapeutics to tackle breathing disordersi and evidence of medicated plaster use for skin ailments in China dates back to ~2000BCii. Oral drug delivery has long been recognised as one of the simplest ways to deliver a remedy, and remains the go-to choice to this day, with around 60% of small molecule drug substances currently delivered via this routeiii.

Over the many years that we’ve been making pharmaceutical testing equipment, our collective ability to engineer products for successful drug delivery via these established routes has advanced at an incredible pace. Pharmaceutical testing has evolved similarly though some tests have remained unchanged. Here we survey the commercial evolution of different pharmaceutical products from the perspective of our experience of pharmaceutical testing, setting the scene for areas we’ll be covering in our blogs in more detail over the coming months.

Testing tablets

We began making products for pharmaceutical testing in the 1950s, targeting tablets due to their dominance in the market. With oral solid dosage (OSD) forms we’re looking for products with physical integrity – stability being a primary attraction – that readily break down and dissolve in vivo to yield the required drug delivery profile. Compendial methods for assessing hardness and friability – the tendency of a tablet to chip, crumble, or break – quantify physical stability. Disintegration and dissolution testing address product breakdown and drug release in vivo, with dissolution testing the primary in vitro method for comparing the bioavailability of different product forms.

Often, the goal of OSD formulation is rapid drug release for the fast relief of symptoms. However, sustained release products have been in the market since the 1950s and controlling the release profile remains a primary focus for many. Dissolution testing is a vital tool for both camps, for both development and QC, and of course, for the demonstration of bioequivalence, for generics. Compendial methods have evolved to ensure an effective approach to dissolution testing for the steadily diversifying range of OSD product forms, with trusted techniques adapted to meet today’s informational requirements.

Topicals, transdermals, and transmucosals

The transmucosal drug delivery products that we focus on, namely suppositories for rectal and vaginal administration, have much in common with tablets from a testing perspective. But when it comes to dermal delivery, we see different testing requirements linked with the specific challenges of the route.

Products for dermal drug delivery include topicals for local action, typically semisolids – ointments, creams, lotions, and gels – and transdermal drug products (TDPs) such as patches, designed for systemic action. Both are subject to product quality testing, such as apparent viscosity for semi-solids and tack and adhesion for patches, and performance testing which focuses on drug release and delivery. Drug is released from the formulation matrix onto and into the skin which presents a considerable barrier to drug transport. For topicals this is desirable but systemics must overcome this barrier, a clear differentiator. Methods for performance testing for TDPs have consequently expanded beyond the simple measurement of dissolution from the product matrix to include the kinetics of membrane transfer.

Introducing inhaled drug delivery

From the 1950s to the 1980s therapeutic aerosols underwent a transformation. The first metered dose inhaler (MDI) was introduced in 1956, by Riker Labs, and by the 1980s several big pharma companies had joined the growing market for both MDIs and dry powder inhalers (DPIs). This was tough technology to crack and the scientists working in the field were a relatively small, close-knit group, often using in-house testing techniques. We launched our first inhaler testing products in the late 1980s as consensus and the regulatory framework regarding testing practice became established.

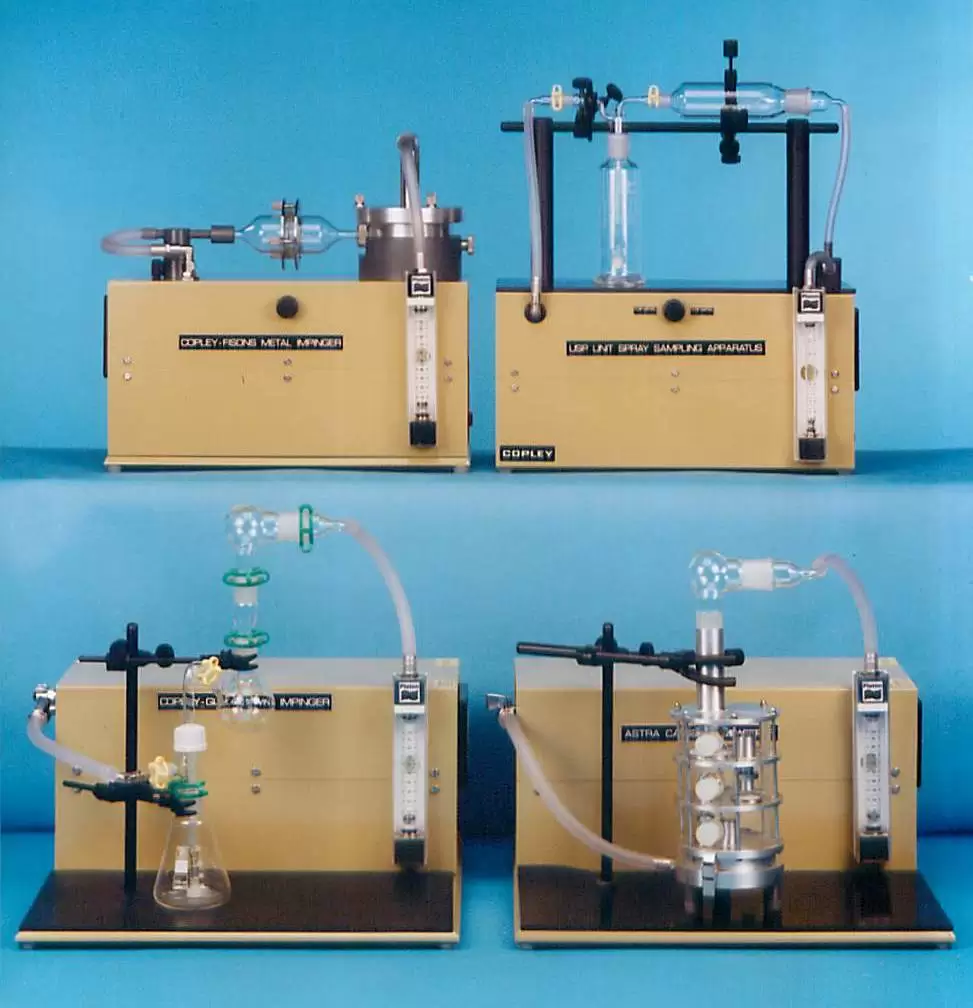

Some of our earliest equipment for OIP testing: dose uniformity sampling apparatus (top right) and various designs of glass impinger (all other images)

Some of our earliest equipment for OIP testing: dose uniformity sampling apparatus (top right) and various designs of glass impinger (all other images)

From the 1950s to the 1980s therapeutic aerosols underwent a transformation. The first metered dose inhaler (MDI) was introduced in 1956, by Riker Labs, and by the 1980s several big pharma companies had joined the growing market for both MDIs and dry powder inhalers (DPIs). This was tough technology to crack and the scientists working in the field were a relatively small, close-knit group, often using in-house testing techniques. We launched our first inhaler testing products in the late 1980s as consensus and the regulatory framework regarding testing practice became established.

Test apparatus for OIPs has changed beyond recognition since the 1980s: cascade impactor set-up for MDIs

Test apparatus for OIPs has changed beyond recognition since the 1980s: cascade impactor set-up for MDIs

Drug delivery via the lungs and nose using orally inhaled and nasal drug products (OINDPs) calls for radically different test methods from those already discussed due to the unique challenges associated with these routes.

For orally inhaled products (OIPs), drug delivery relies on dose dispersion to a respirable size, typically 1 to 5 microns to deposit deep in the lungs. Inhaled products ‘power’ this dispersion process in different ways – nebulisers use a compressed air or ultrasonic device, MDIs use a propellant, DPIs rely solely on the inhalation manoeuvre of the patient. But in each case the impact of the device depends on the physical characteristics of the formulation. The same is true for nasal drug products. Furthermore, the technique and physiology of the patient also have an impact. This substantial complexity differentiates OINDPs from any other drug product and therefore defines test requirements and practice.

Key methods include delivered dose uniformity testing and cascade impaction, a technique that measures aerodynamic particle size distribution for the drug substance within a formulation. Tests are carried out under different air flow regimes to reflect patient use. We became pioneers in the field of OINDP testing, with precision engineered cascade impactors for routine OIP testing an important early contribution, and today we continue that fascinating journey as in vitro testing evolves to support the greater utility of these valuable routes.

Changes and challenges

Working as we do across different drug delivery routes gives us perspective on how the chosen route impacts the challenges faced, and how that in turn shapes the information required from development through to QC. In vitro testing practice is shaped by these informational requirements and continues to evolve in line with impressive advances in drug delivery technology.

In the OSD area, poorly soluble and poorly permeable drugs are being tackled with techniques such as pharmaceutical crystal engineering and self-emulsifying solid dispersions. Nanocarriers, innovative films and microneedles are all features of the TDP market while in the nasal drug delivery arena we see growing interest for systemics, for vaccines, and for nose to brain drug delivery. Intimately entwined with all these trends is the shift towards biologics and the associated need for drug delivery methods that avoid first pass metabolism. Injection and infusion are primary delivery routes for biologics but dermal, nasal, and pulmonary delivery, all hold promise with respect to higher patient acceptance.

In every area there is a need to maximise the relevance of in vitro testing since more effective in vitro and in silico studies mean fewer/less expensive in vivo studies and faster time to market. So, plenty to for us to continue working on.

To find out more about pharmaceutical testing for different delivery routes why not download our new whitepaper which provides much more detail on this interesting topic as well as summarising key compendial requirements.

Or look out for our next blog on Wednesday 25th October which will begin a more detailed consideration of different delivery routes and how they shape testing practice: first up, a deeper dive into the intricacies of inhaled drug delivery.

i S. W. Stein and C.G. Thiel. The History of Therapeutic Aersosols: A Chronological Review. J Aerosol Med Pulm Drug Del. 2017 Feb 1; 30(1): 20–41.

ii M. N. Pastore, Y. N. Kalia, M. Horstmann, and M.S. Roberts. Transdermal patches: history, development and pharmacology. Br J Pharmacol. 2015 May; 172(9): 2179-2209

iiiM. S. Alqahtani, M. Kazi, M. A. Alsenaidy, M. Z. Ahmad. Advances in Oral Drug Delivery. Front. Pharmacol. 19th Feb 2021.