Contact Us

Contact Us

Please select an option:

Nasal sprays typically produce droplets in the range 20-200 microns, which is outside the effective range of cascade impactors. However, most sprays typically deliver a proportion (typically <5%) of fine droplets in the <10 micron range, which must be quantified.

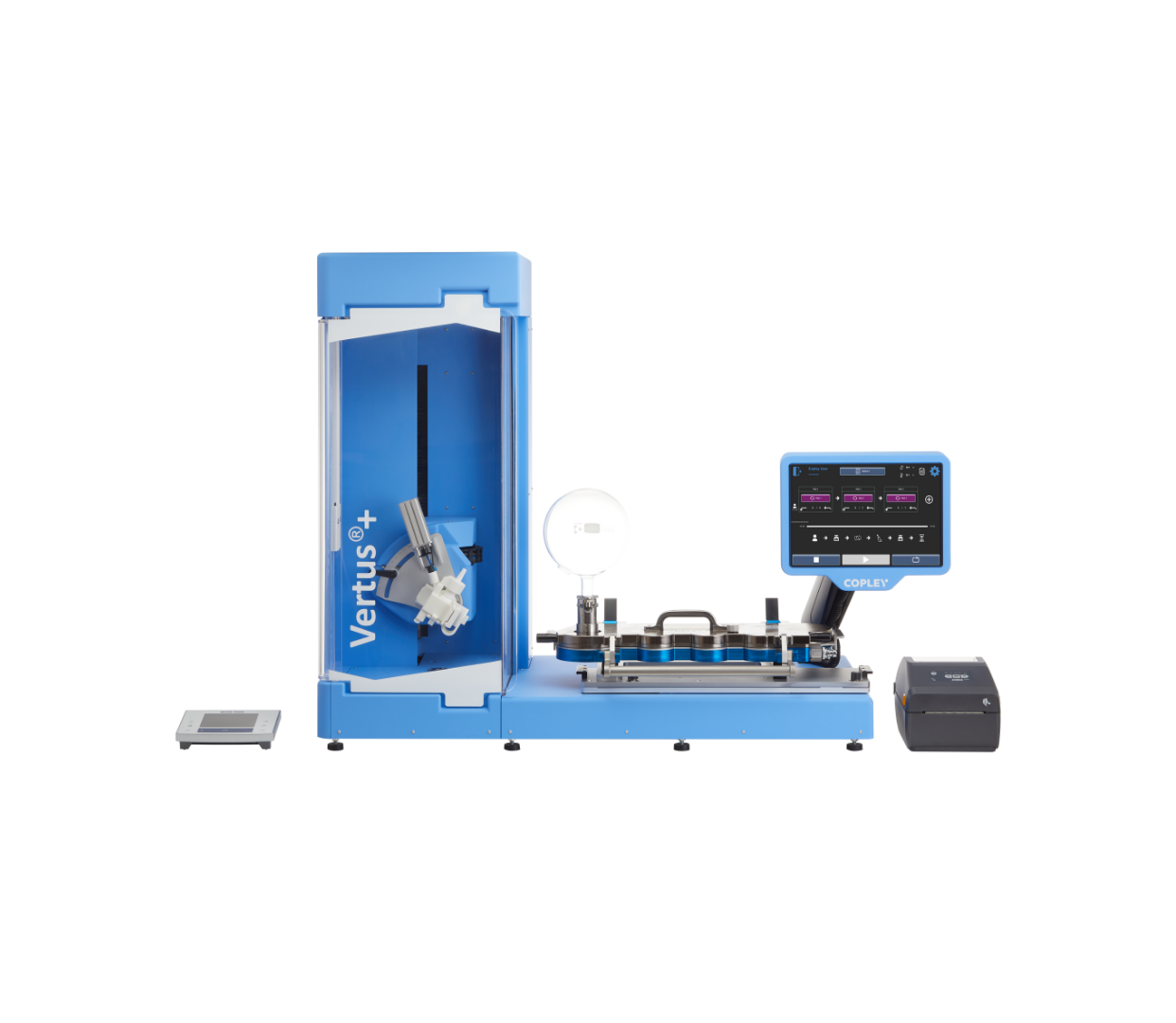

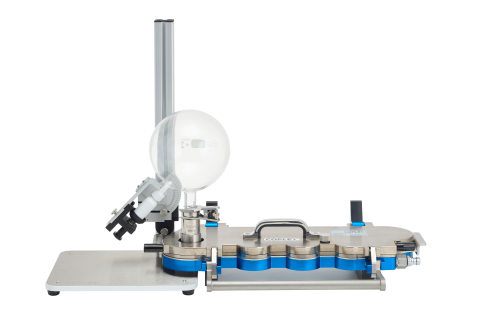

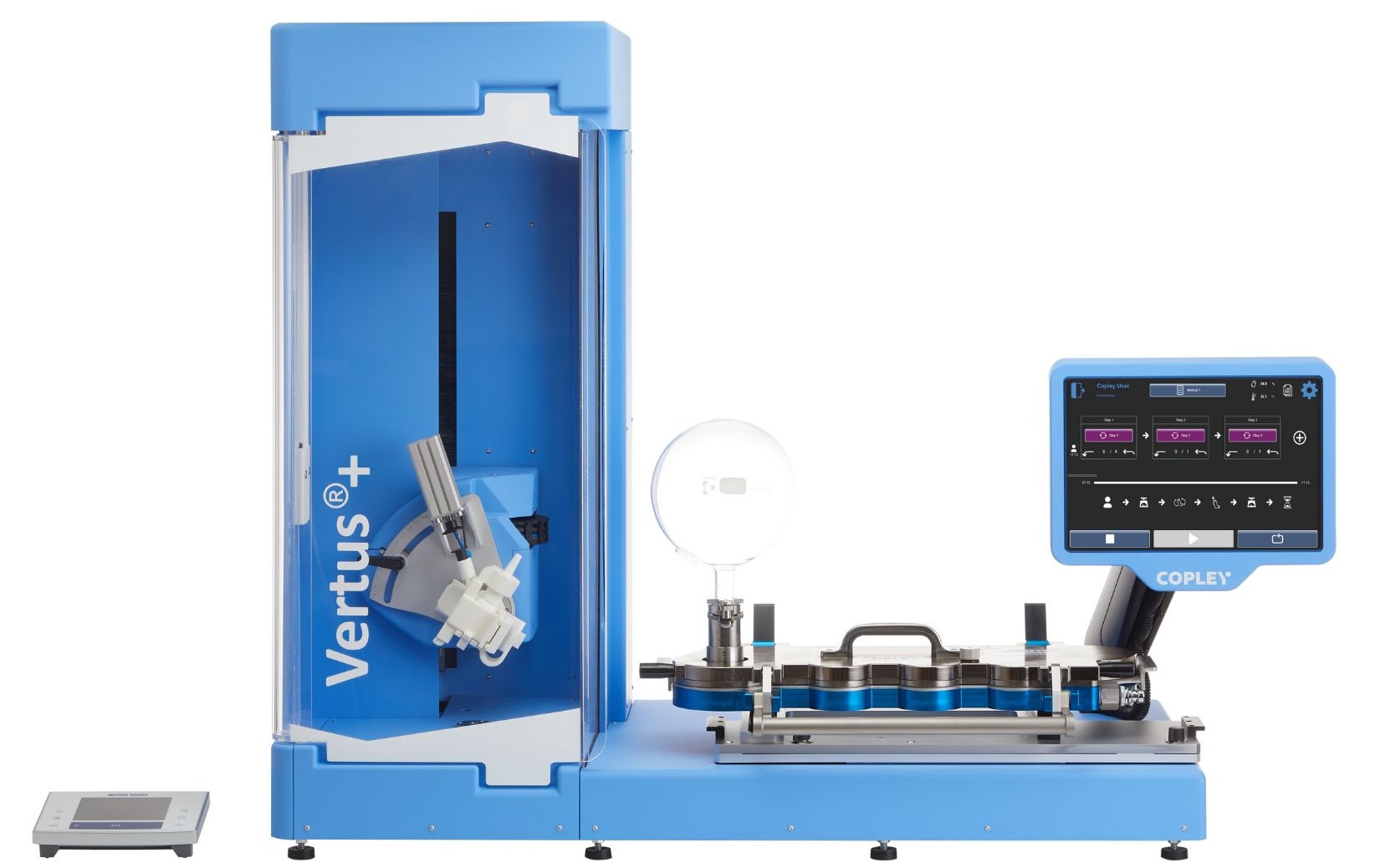

Used together with a cascade impactor such as the Next Generation Impactor (NGI) and a high volume expansion chamber, such as the Glass Expansion Chamber, the Vertus® III/Vertus® III+ automated shake, fire and flow control systems can be used to meet the need for highly consistent nasal spray actuation as recommended by USP <601>.

Shot weight measurement

The Vertus® III+ model includes an integrated analytical balance for automated nasal spray shot weight measurement.

Please select an option:

Please select an option:

Nasal Sprays: Automated APSD Measurement

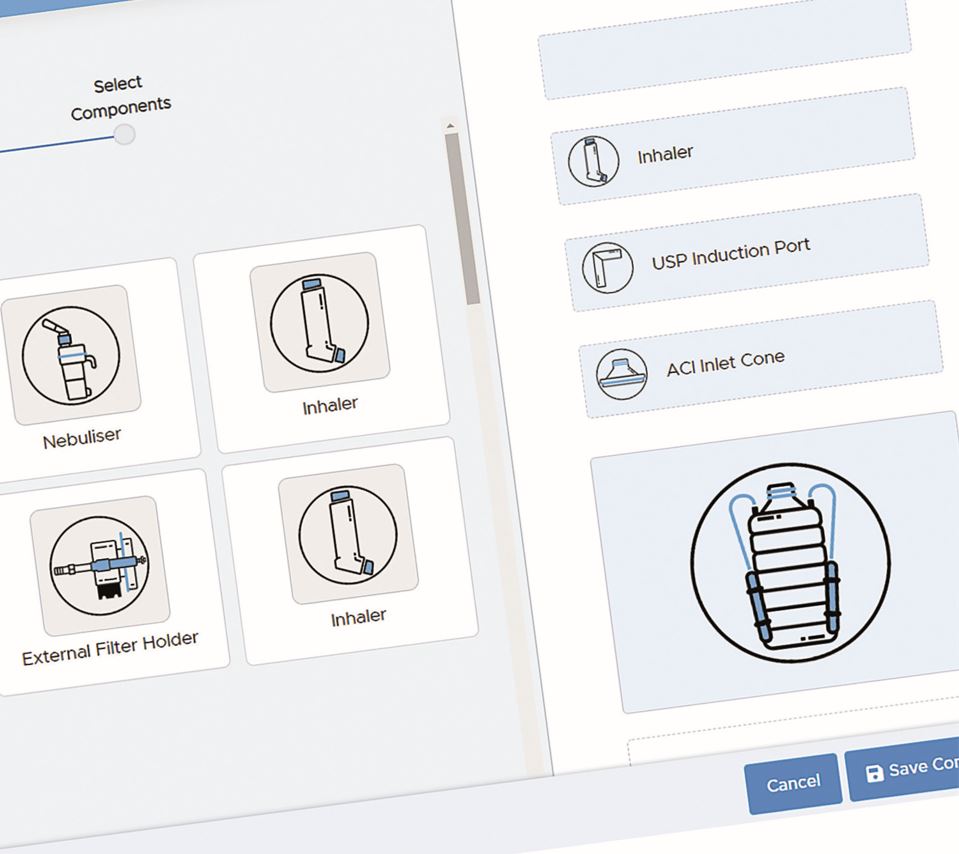

The Vertus® III automated shake, fire and flow range is made up of integrated turn-key solutions for precise, controlled and reproducible nasal spray testing. Compatible with most nasal sprays, the Vertus III or Vertus III+ offers analysts complete control over:

- The speed, angle and duration of shaking, ahead of actuation

- Firing force and the speed of application and release of that force

- The time delay between the end of shaking and device actuation

How Does a Cascade Impactor Work?

Related Applications

We also offer a range of equipment for additional nebuliser testing application support:

Semi-Automation Tools

Related Services

Training

We offer a range of training courses, presentations and seminars covering a wide range of topics.

Find Out More

Servicing

A comprehensive range of both in-house and on-site product servicing options are available

Find Out More

Support

Our team of experienced technicians and engineers are on hand to help and advise

Find Out More