Home > Inhaler Testing > Aerodynamic Particle Size Distribution (APSD) > APSD of Soft Mist Inhalers (SMIs) > SMIs

APSD of Soft Mist Inhalers (SMIs)

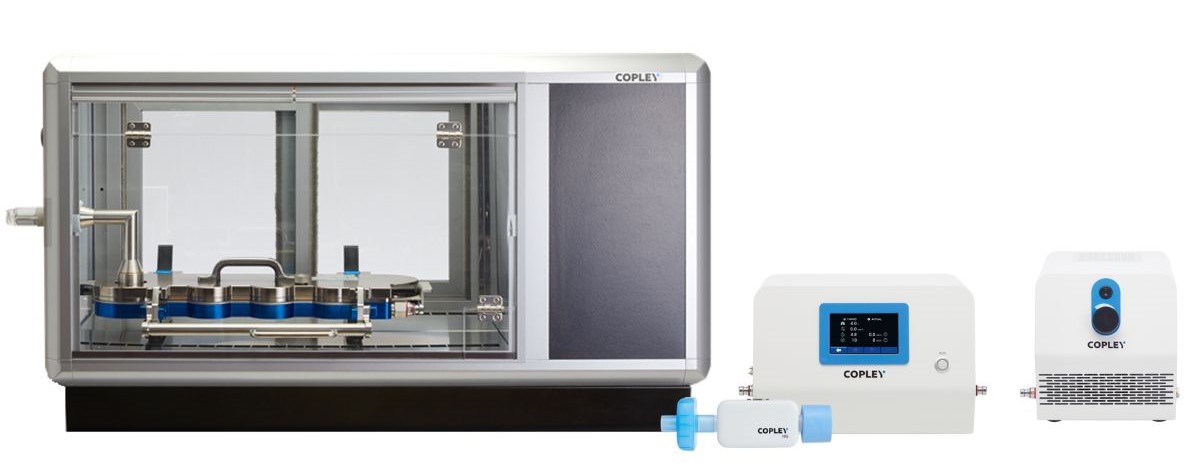

For ADIs as for nebulisers, the evaporation of droplets exacerbated by the thermal mass of the impactor can be a problem. Loss of solvent reduces droplet size, producing artificially low APSD measurements, compromising the integrity of the resulting data. Cooling the impactor to approximately 5°C is the recommended method for overcoming this problem. Classified as active devices, the recommended flow rate for ADI testing is 28.3 L/min for the ACI or 30 L/min for the NGI.

Contact Us

Contact Us

Enquire about SMIs

Andersen Cascade Impactor (ACI)

Mouthpiece Adapter

View BrochureNGI Induction Port

View BrochureNext Generation Impactor NGI

View BrochureBAC 100i Breath Actuation Controller

View BrochureLCP6 Low Capacity Vacuum Pump

View BrochureFlow Rate Sensor FRS

View BrochureNGI Cooler™

View BrochureInhalytix® – APSD Data Analysis Software

View BrochureTemperature and Relative Humidity Sensor

View BrochureFootswitch

View BrochureNGI Cup Rack

View BrochureNGI Carrying/Washing Rack

View BrochureInternal/External Filter Holder

View BrochureDFM 2000 Flow Meter

View BrochureHCP6 High Capacity Vacuum Pump

View BrochureNGI Cooler™ Shelf

More detailsDDU of Soft Mist Inhalers (SMIs)

View SystemMouthpiece Adapter

View BrochureNGI Induction Port

View BrochureNext Generation Impactor NGI

View BrochureBAC 100i Breath Actuation Controller

View BrochureLCP6 Low Capacity Vacuum Pump

View BrochureFlow Rate Sensor FRS

View BrochureNGI Cooler™

View BrochureInhalytix® – APSD Data Analysis Software

View BrochureTemperature and Relative Humidity Sensor

View BrochureFootswitch

View BrochureNGI Cup Rack

View BrochureNGI Carrying/Washing Rack

View BrochureInternal/External Filter Holder

View BrochureDFM 2000 Flow Meter

View BrochureHCP6 High Capacity Vacuum Pump

View BrochureNGI Cooler™ Shelf

More detailsDDU of Soft Mist Inhalers (SMIs)

View SystemRelated Applications

We also offer a range of equipment for additional DPI testing application support:

Related Applications

Two factors have been identified as being critical to improving the clinical relevance of DDU testing and APSD measurement: realistic breathing profiles and realistic throat and nasal models.

View More

Automation Tools

Automation Tools

Copley supplies a broad range of labour-saving devices and semi-automated systems for Aerodynamic Particle Size Distribution applications.

View Product Range

Sample Preparation Unit SPU 200i

Copley supplies a broad range of labour-saving dev…

View Product RangeAutomation Tools

Copley supplies a broad range of labour-saving devices and semi-automated systems for Aerodynamic Particle Size Distribution applications.

View Product Range

Automation Tools

Copley supplies a broad range of labour-saving devices and semi-automated systems for Aerodynamic Particle Size Distribution applications.

View Product Range

How Does a Cascade Impactor Work?

Play VideoRelated Services

Training

We offer a range of training courses, presentations and seminars covering a wide range of topics.

Find Out More

Servicing

A comprehensive range of both in-house and on-site product servicing options are available

Find Out More

Support

Our team of experienced technicians and engineers are on hand to help and advise

Find Out MoreRelated News & Resources

Have a question? Our friendly and experienced team are here to help.